SERVICING – ABU Ambassadeur 4500C

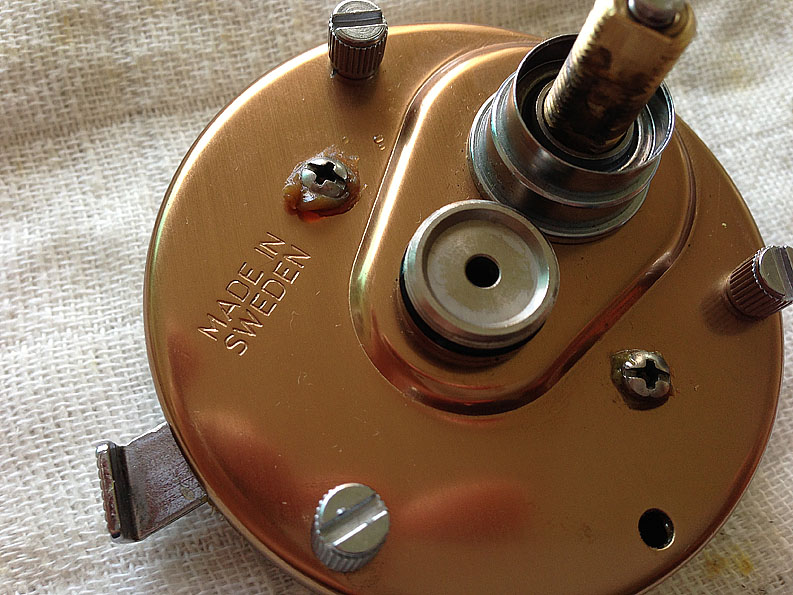

Here is another reel from my friend’s collection of Ambassadeurs that he passed me to service. Even though this is a relatively modern incarnation of the venerable ABU Record Ambassadeur Casting reel, it has retained most of Ambassadeur’s simple design so servicing this immediately after doing the Shimano Antares DC7 was a breeze by contrast.

I’ll start this step by step guide with a few shots of the reel before I cracked it open.

Familiar Ambassadeur Sideplate

A wise author once said, fashion comes and goes, but a good style will stand the test of time. ABU Ambassadeurs have worn this same face for decades. Yet each time I look at it, I never feel that it is out of style!

“500” in the model number tells us that this is a high speed reel, and “C” says its got ball bearings for the spool.

Retro Look

Creases on the sideplate flanges hark back to the old pioneering days of the ABU Record Ambassadeur.

No more need for oil?

The Handle nut on this newer reel has lost it’s distinctive “Oil” word stamped into the face. The finish is also rather crude compared to the older Handle nuts. The dimpled-finish handle crank looks cheap compared to the dimpled-finish spool cap. I got this feeling that these are aftermarket replacements.

New reel foot numbers.

I’m not familiar with these new reel foot numbers and what they represent. Anyone care to enlighten?

Pitting on spool flanges

Corrosion on the spool flange does not bode well. Hopefully, things are better inside.

Panoramic shot Fail. Reel parts Pass!

I took off the left sideplate to service first. The GREAT thing of an Ambassadeur is its modular nature. You can commit to only servicing one part at a time, compared to other reels where you are COMMITTED to finish the full monty once you crack the reel open. AS for my photography skills… I’m still learning to use my phone. hahaha.

Marine Grease protection

Coat the inner surfaces of this left sideplate with Quiksilver 2-4-C marine grease for corrosion resistance. The idler gear seem to have become permanently riveted down. Since the owner will be using this reel for casting, I’ll use a light oil for lubrication.

Grease the frame in similar fashion but take care to avoid getting grease on the aperture where the spool flanges rotate. Doing so will adversely retard casting distance.

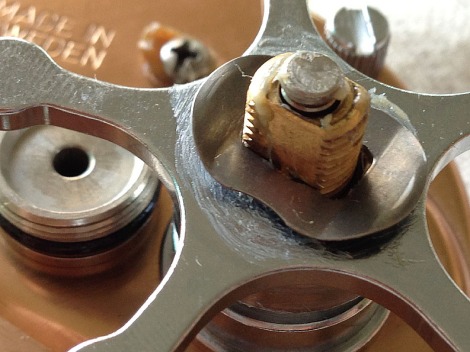

Levelwind Assembly

Slide worm gear cover through levelwind guide, ensuring you match the worm cover with keyholes in the frame and the guide is sitting in a groove in the frame.

Oil worm gear. I used a dry lube called TSI-301 on it since this will be used for casting. Slide worm gear into its cover.

Snap levelwind yoke over the plastic collar of worm gear to secure.

Oil levelwind pawl with a light oil and install. Here, I also used TSI-301 dry lube.

Thread in the pawl cap and tighten, taking care not to over torque.

Fit back the left side plate and secure with 3 stainless screws. Remember to grease the threads before you thread them in and do not over torque when tightening.

Finishing up left sideplate assembly

The 4500C uses a brass cone in place of bearings. The ball bearings are sited within the spool. Oil the cone with a light oil and drop in with the hole facing down.

Oil the threads of Cast Control knob with Cal’s grease or corrosionX. Thread on the cast control knob and the left side is done!

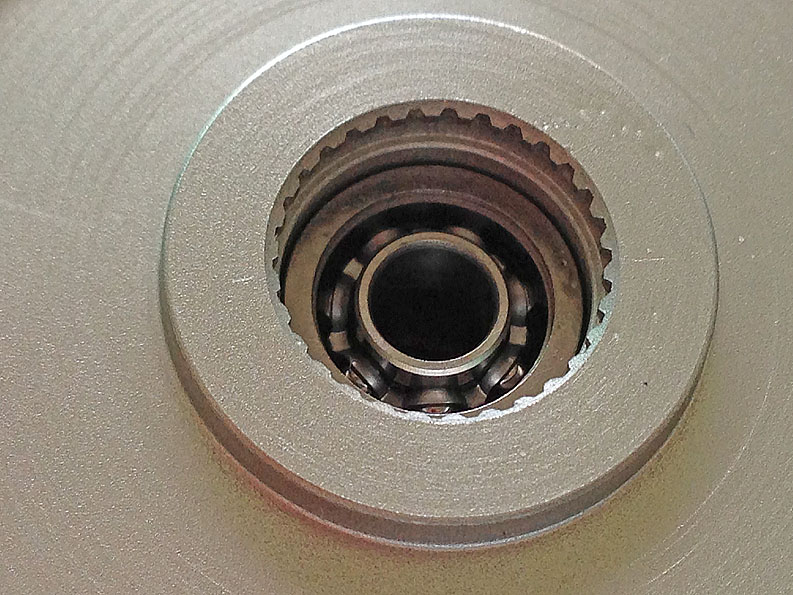

Spool and Bearings

The Ball bearings are protected within the spool. To access them, carefully pry out retaining circlip within a clear plastic bag to prevent them flying off and spoiling your day. The centrifugal braking assembly, right ball bearing and a copper spring washer will slide out.

For the left side, carefully snap the nylon levelwind gear off to expose the left ball bearing.

Unshielded bearings can spin better

When I tried to spin the bearings, it could only give me a second or two of rotation. I used a sharp hook to dig out the C clips on each side of the ball bearing and the shields will come out after the grease has been washed away. To learn how to remove Ball Bearing Shields, click this

After cleaning the two ball bearings, I’m pleased to find out that ABU ball bearings are still so silky smooth, they’re capable of out-spinning some modern ABEC 7 bearings! Here’s how smooth it is after cleaning… I decided to record how long the bearing will spin after cleaning so I gave it a blast of air when I recorded it on video . I didn’t expect it to spin for so long that I almost ran out of things to say and yet the bearing continued to spin… I lubricated the ball bearings with TSI-301 dry lube. (Somehow, I’m unable to insert a link for you tube videos). For those who wanna view this video, type: youtu.be in front of this: /-Pgj2j0Yem0

Spool reassembly

Drop in copper spring washer with the convex side facing outwards.

Next to go in is the lubricated ball bearing.

And then the Centrifugal brake assembly secured by a Circlip.

Drop second ball bearing into the left side. These spool bearings are lubricated with a revolutionary “dry” lubrication called TSI-301 that enhances casting distance and reduces breakaway torque, so you can cast lighter lures than before.

Carefully align the sprockets on nylon levelwind gear with those on spool and snap in place. Your spool servicing is done.

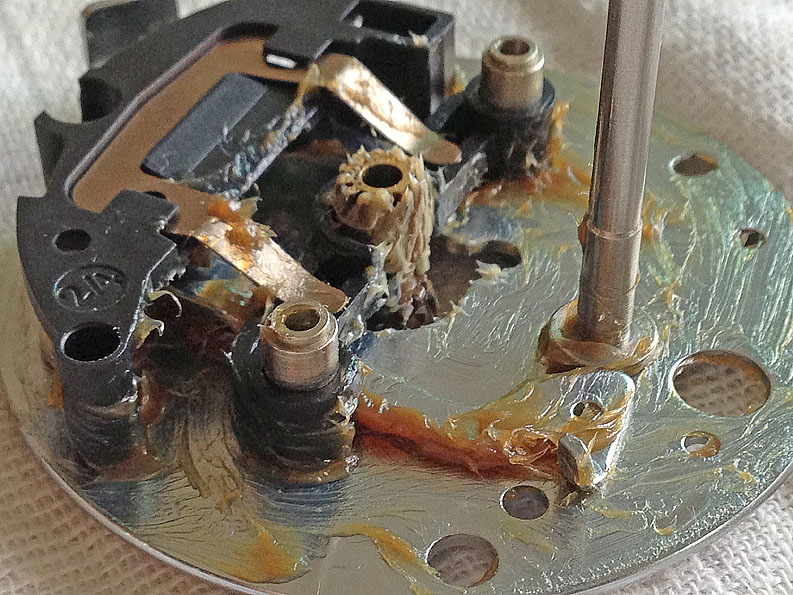

The right side dismantled

The Ambassadeur design is still as uncomplicated as before, despite the addition of a multi-piece carbon drag.

Smoother, more powerful drag

With the addition of 2 steel washers, this Ambassadeur will have 3 times more drag power than its earlier ancestors.

Neat freespool mechanism is riveted in place.

With a Delrin yoke, copper springs and everything riveted in place, there seem to be little left to be done here.

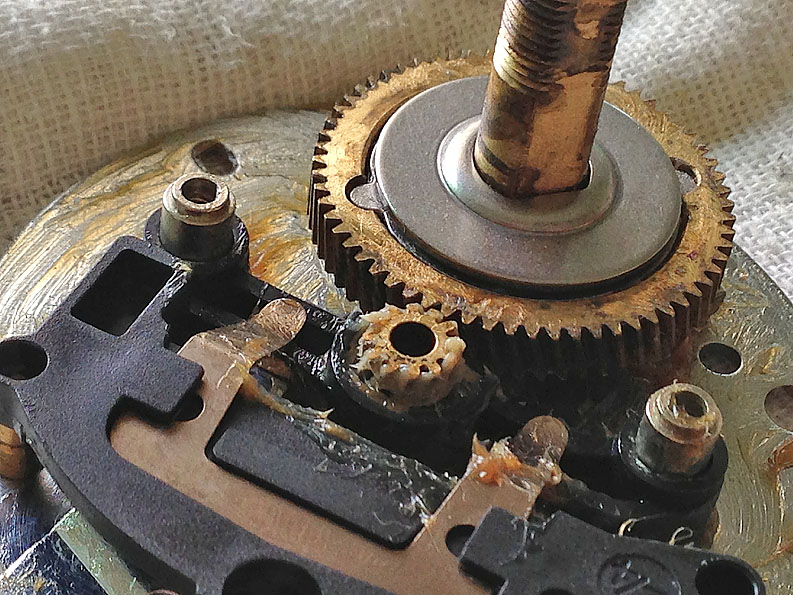

Assembly of right side plate

Start with grease protecting the components. I also greased the pinion with Cal’s Universal Drag and Reel Grease.

Slide copper spring washer down drive shaft spindle with the convex side facing down.

Grease drive shaft and anti reverse ratchet. Slide down drive shaft spindle.

Drop in small carbon matrix disc, lightly grease with Cal’s grease.

Drop in main drive gear.

Lightly grease both sides of a large carbon matrix disc and drop into main drive gear.

Lightly grease keyed washer with Cal’s grease and drop in main drive gear.

Lightly grease both sides of 2nd large carbon matrix disc and drop into main drive gear.

Lightly grease both sides of eared washer and drop into main drive gear.

Lightly grease both sides of 3rd large carbon matrix disc and drop into main drive gear.

Drop in thick keyed washer with the convex side facing up.

Grease main drive gear with Cal’s Grease, taking care to work the grease in between all the teeth.

The roller clutch inner tube has a keyed end and a round end.

Oil roller clutch inner tube lightly with CorrosionX oil and drop down drive shaft with keyed end facing down. This is not the normal way I mount the roller clutch inner tube (usually the keyed end faces up). But this reel has the keyed end facing down when I opened it, and I notice the round end has a chamfered edge, so I’ll just reassemble it the way I took it out.

Coat the inner surfaces of right sideplate cover with Quiksilver 2-4-C marine grease for corrosion resistance. Take care to avoid getting grease into the roller bearings as grease may cause the clutch to slip.

Attach cover to right side plate and secure with greased screws.

These two belleville washers make up the drag spring. I’ll install them opposed like ( ) for a greater drag range.

Grease and thread in star drag and spring washer

Grease and place in handle assembly

Secure drive shaft to spindle with E-clip

Cinch down star drag firmly, then secure with handle nut, locking plate and screw.

This reel’s spool spins on a floating spindle. Oil both ends of the spindle with CorrosionX, taking care not to get the oil or grease beyond the bronze bush. Introduce spindle into pinion and click in place with the spool tension cap.

This spool tension cap can be adjusted to centre the spool.

Spray some WD-40 down the handle knob shafts till dirty oil comes out the other ends. Spin knobs to hasten cleaning. Continue to do this till only clean oil emerges. Clean off the WD-40 with a blast of compressed air and oil knobs with 2 drops of CorrosionX per spindle.

The reel is now ready for line to be loaded. Hopefully the owner knows how to control the additional speed of this reel’s super smooth bearings.

Hope it help you service your reel too. Do drop a comment below to say hi!

Good fishing always,

LL

I hope this step-by-step guide helped you in servicing your own reel too. If you found this useful, please click the blue LIKE and FOLLOW buttons. If you would like me to help you service your reel, or if you would like to help me with the cost of keeping this blog running, please drop me a message via WhatsApp at +65-9431-0400. Thank You!

Text and Images © Lawrence Lee

All Rights Reserved

If you want to use any content for your own publication, please write me @ Lee.TC.Lawrence@gmail.com

I was given a 1977 Abu Ambassadeur bait casting reel. I am a neophyte to using bait casting gear. I started filling the reel with line but had to stop for a few minutes to answer a telephone call. When I started lining again, the crank did not retrieve line. It spins freely. I did not drop the reel. The star drag and casting mechanism work. The crank does not spin in the reverse direction. Any ideas?

Does the spool turn?

The spool turns manually, but not by using the crank.

Tighten star drag. Pull line to see if there’s greater resistance after tightening. If none…

Check that the pinion is engaged to the spool shaft. If it is, you’d need to open the reel up to check if your pinion teeth have all worn out and are not meshing to the main gear. While you’re at that, check the drag pieces are also not worn or jammed

When the drag is completely tightened, the crank retrieves line. If I loosen the drag even slightly the crank does not retrieve line. Unfortunately I do not know how to answer your question about the “pinion is engaged to the spool shaft”.

Sounds like the drag discs have dried up and got hard. You’d need to strip the reel in order to service that.

“strip the reel” ?

Yes. If you have the tools and know how. You can follow my blog as a general guide

Yes the drag works. “Tighten star drag. Pull line to see if there’s greater resistance after tightening”.

I failed to mention that the reel was made in 1977 but is in mint condition. I do not believe it was ever fished. It has one small scratch on the crank-side rim near the foot. Other than that – pristine. I carefully tried to remove the oil cap with pliers but stopped because I could not apply sufficient torque.

Umm… you need proper tools to do it right. What you may be holding could be a prized possession so you should use proper tools. No pliers as they mark the parts.

I backed off on the pliers

Thank you for your help!

Do you repair reels?

Yes I do reel servicing. I can’t repair if there’s no parts available

I am willing to make washer parts or soak the old ones in in oil, for example, to repair this reel. What do you think?

There is a parts store claiming to have parts if I can identify exactly what I need.

https://www.ereplacementparts.com/abu-garcia-parts-c-187196.html?source=gaws&gclid=EAIaIQobChMIuL6zs5ne8gIVL25vBB2BUgeuEAAYASAAEgI98vD_BwE

Old Ambassadeurs use leather for their drag. Once you get the main gear out, degrease the gear and washers. The old leather should become pliable again. Use drag grease on the washer.

I am not fearful to try to “strip the reel” with the proper tool. However, I am also willing to have an expert perform the tasks. What is your opinion? Thank you for your help!

Where are you at? I’m in Singapore so I can’t help you if you’re not in the country. If you are in the US, try asking around for a reel repair near you at Alantani.com